Printing press replacement for Wifac, at Smurfit Kappa Zedek

At the beginning of this year, we contributed to the replacement of a printing press at Smurfit Kappa Zedek in Deventer. Our client Wifac, with whom we work often, took care of the entire disassembly and assembl and we assisted them with, among other things, lifting activities, unloading machine parts and internal transport.

Printing press replacement: even higher qualiry and flexibility

Within the international Smurfit Kappa Group, Deventer-based Smurfit Kappa Zedek is the specialist in consumer packaging and displays. This places high demands on quality and flexibility in production. That is why they opted for this new investment and to, once again, raise the bar on excellence.

Before the new printing press could be installed, the old press had to be removed. In addition, the floor had to be reinforced before the new printing press was delivered. A major project, in which many different parties were involved.

Dismantling and transport of existing press

We started at the beginning of January. To install the new press, the old press had to be removed first. The Wifac technicians dismantled the press and we then transported it. With our mobile crane we loaded the machine parts of the existing press, transported them to Apeldoorn and stored them in our warehouse.

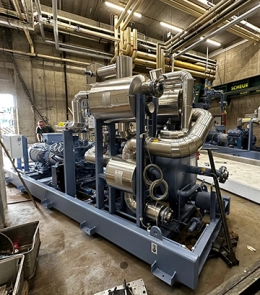

Installation of new press

Subsequently, the foundation was reinforced and adapted for the new press. At the end of February the time had come: the first machine parts were delivered.

To be able to place the new press, we first built up our hydro gantry on the reinforced floor. During three days a total of 11 trucks arrived from Germany with all parts of the new printing press. We unloaded them with the help of electric forklifts and our mobile crane. We rolled in almost 100 pallets and boxes. We were then able to pick up and position all parts of the press with our hydro gantry and unpack all the boxes.

The Wifac technicians took care of the entire assembly of all parts of the new printing press. “Given the weight of approximately 9 tons per part, it takes meticulous work to get them together neatly. After all, the gears had to fit together perfectly,” explains Gerard Oerlemans (Wifac).

Succesful printing press replacement

Everything went well in consultation with Wifac and the Technical Department of Smurfit Kappa Zedek. They have now completed all the last work and the new printing press is running at full power and to full satisfaction! We recently unloaded the old printing press from our storage and it is on its way to a new destination and a happy new owner. What a great project to contribute to!

Find a nice overview in following Timelapse made by Smurfit Kappa Zedek!